PROCESS

1 Start of with some of the finest carbon steel available. Primarily using Hitachi White #1 and Hitachi Blue #1.

2 Primarily using San Mai construction ( mild “softer" steel on the outside or a stainless steel on the outside with a carbon core center) or multi layered Damascus which is all made in shop by me.

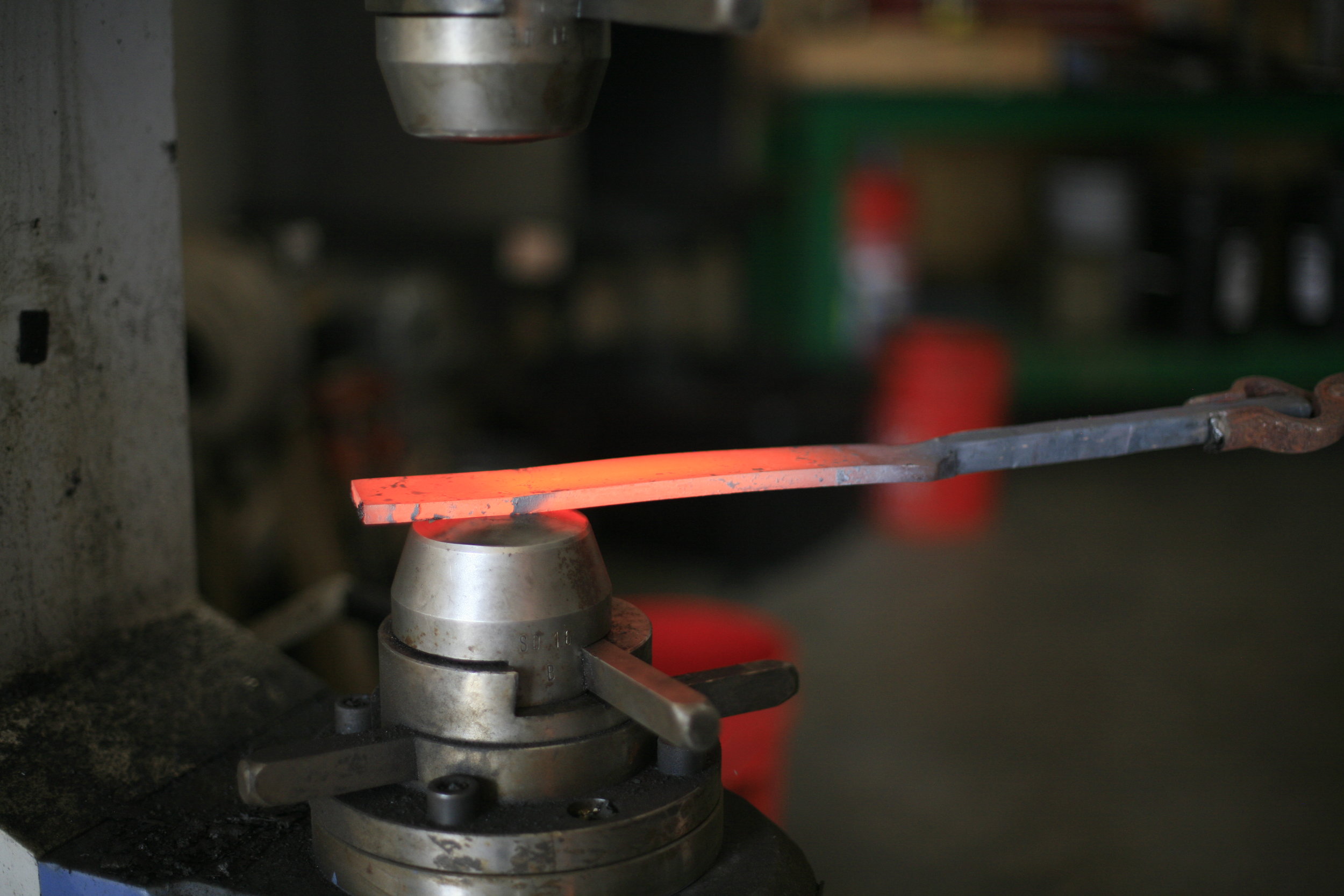

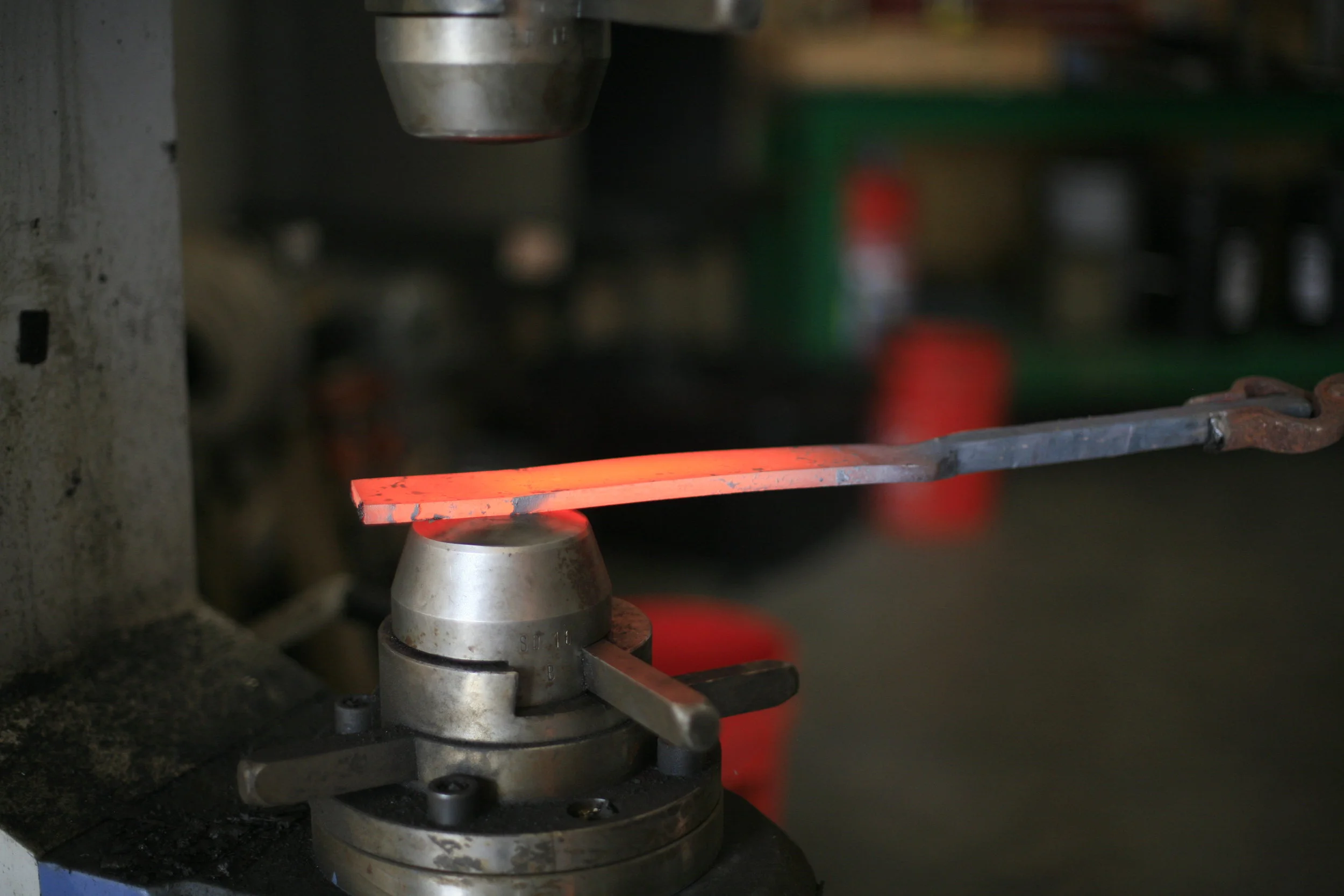

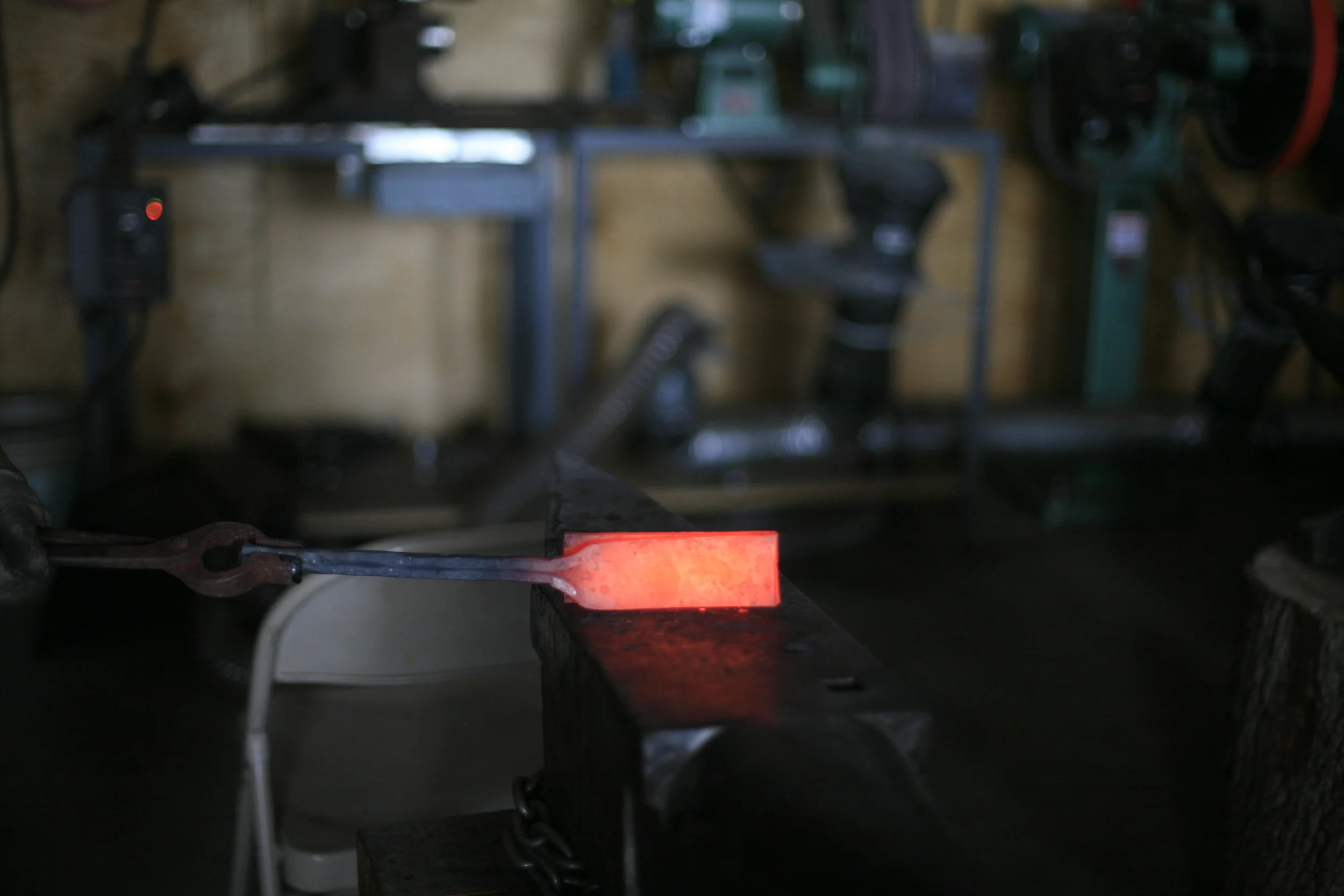

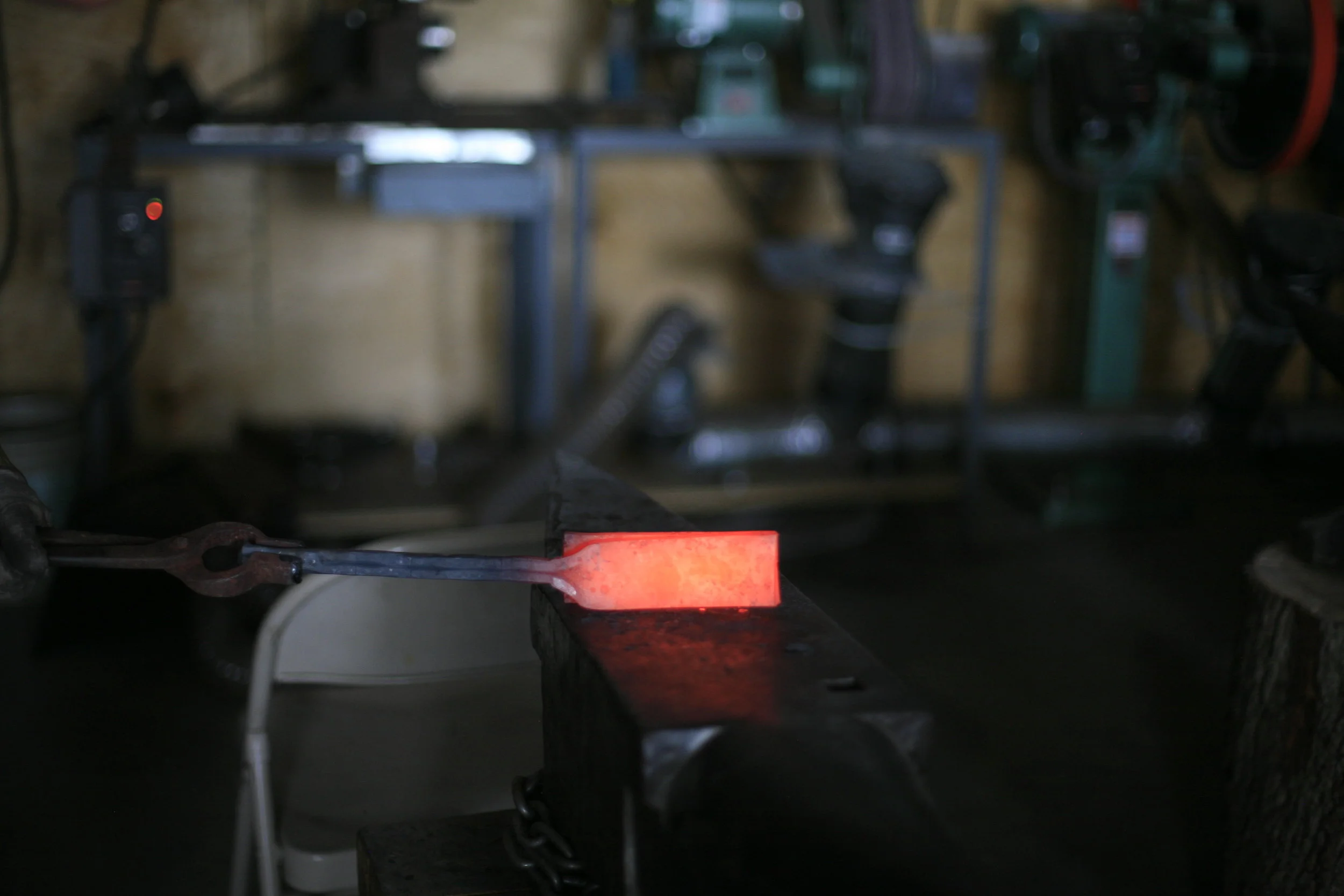

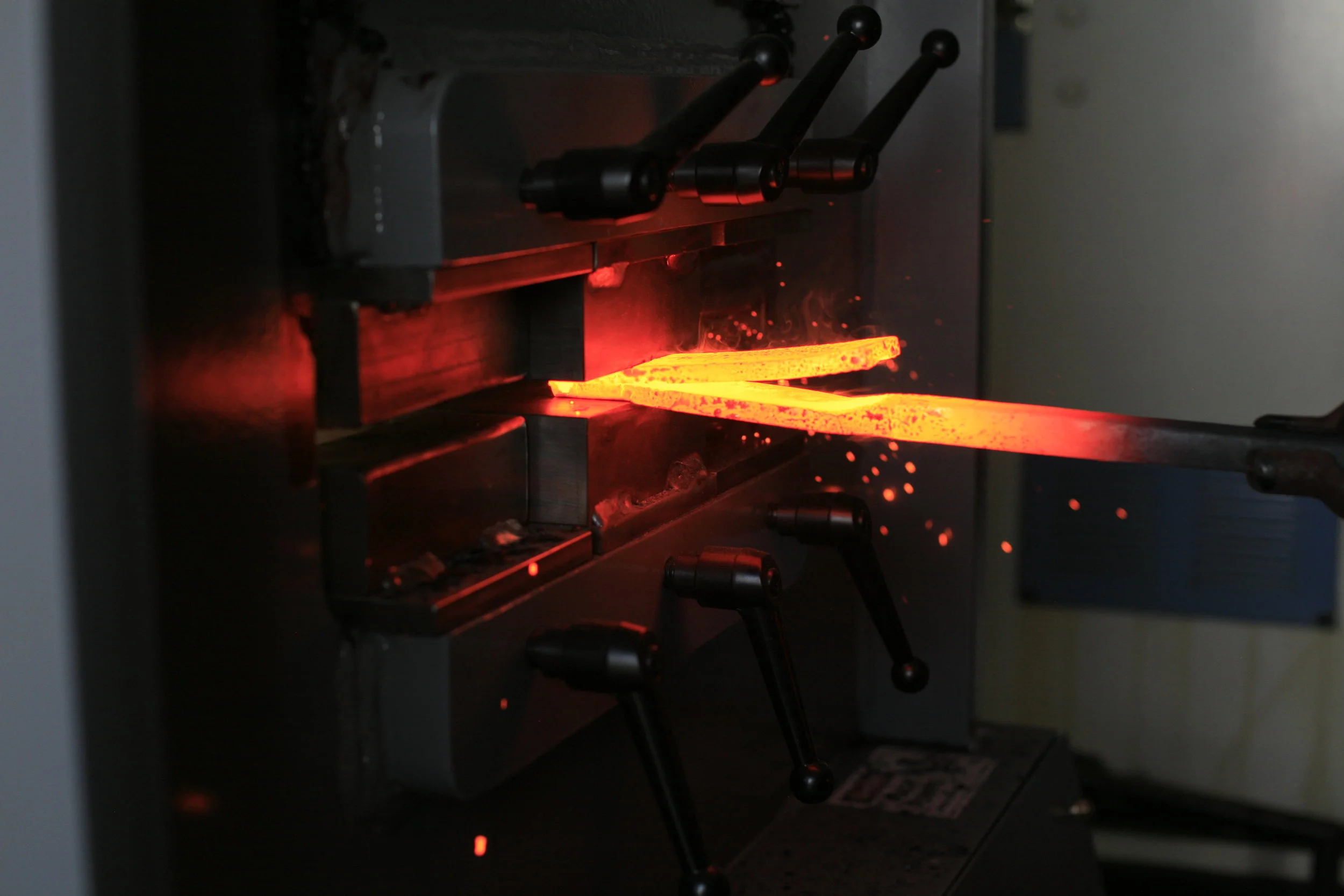

3 All cutlery is forged using a traditional coke forge and hammered to the desired dimensions.

4 After the knife is forged to shaped, each knife is annealed and then cold forged to further refine the grain structure.

5 After cold forging I grind the profile, drill handle scale holes if needed and stamp my makers mark.

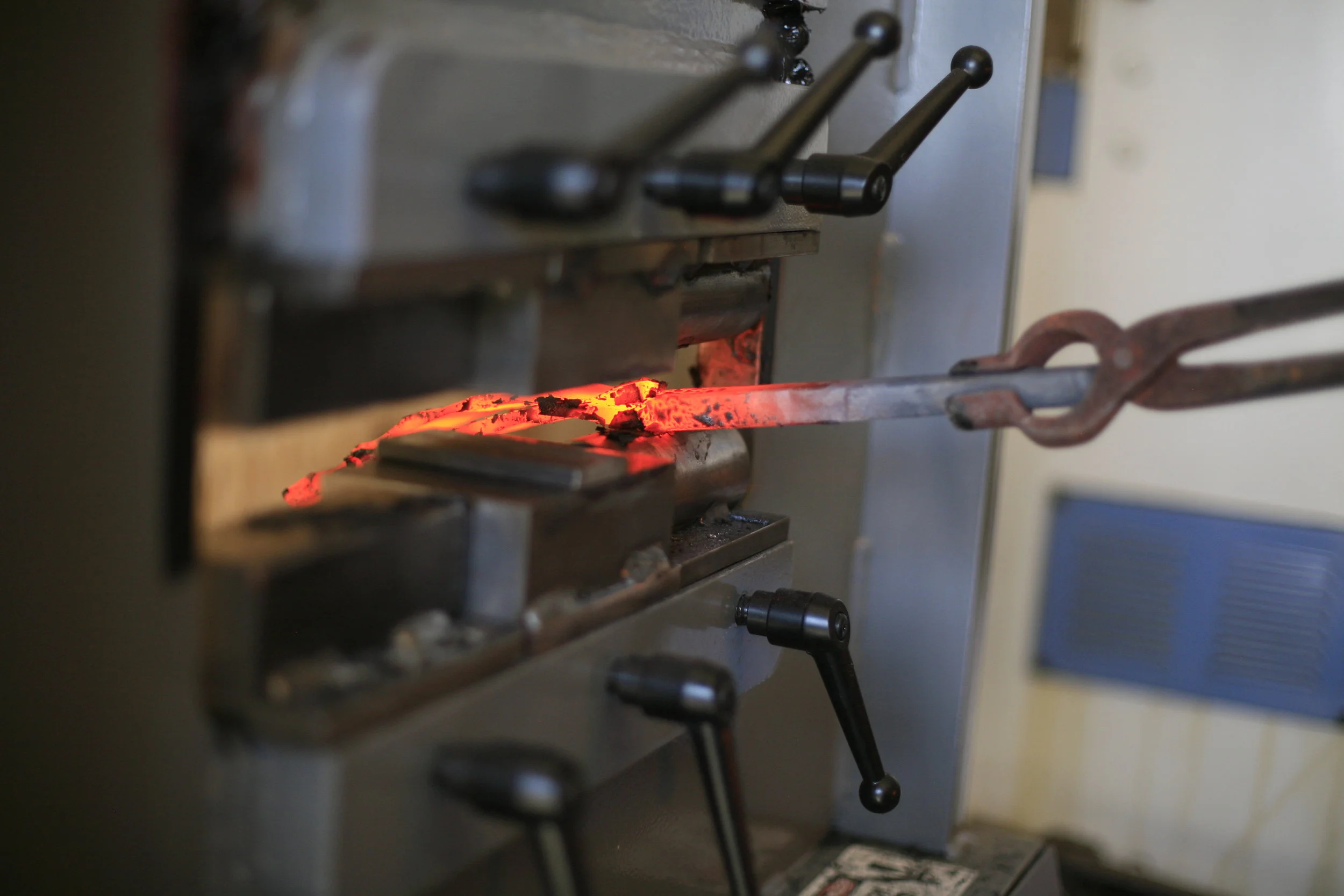

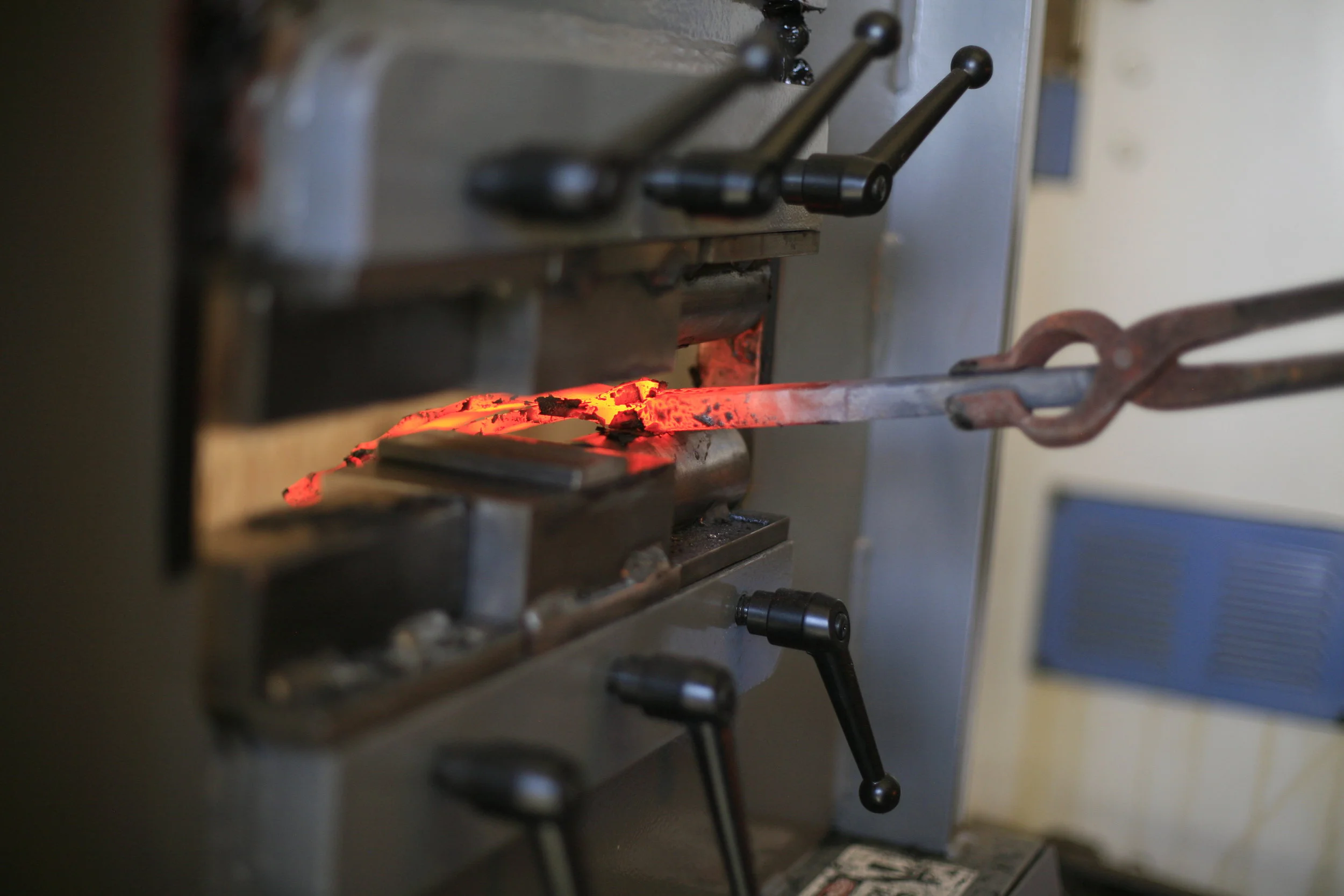

6 Each blade is then coated in clay, heat treated and quenched in water to make the steel as hard as possible.

7 After the quench the blade hardness is tempered back to a hard but not brittle blade.

8 The the knife is ground to the desired edge geometry and sharpened with Japanese water stones.

Use your knife for what it is intended for. Slicing, cutting and piercing. It is not a pry bar, axe, etc…